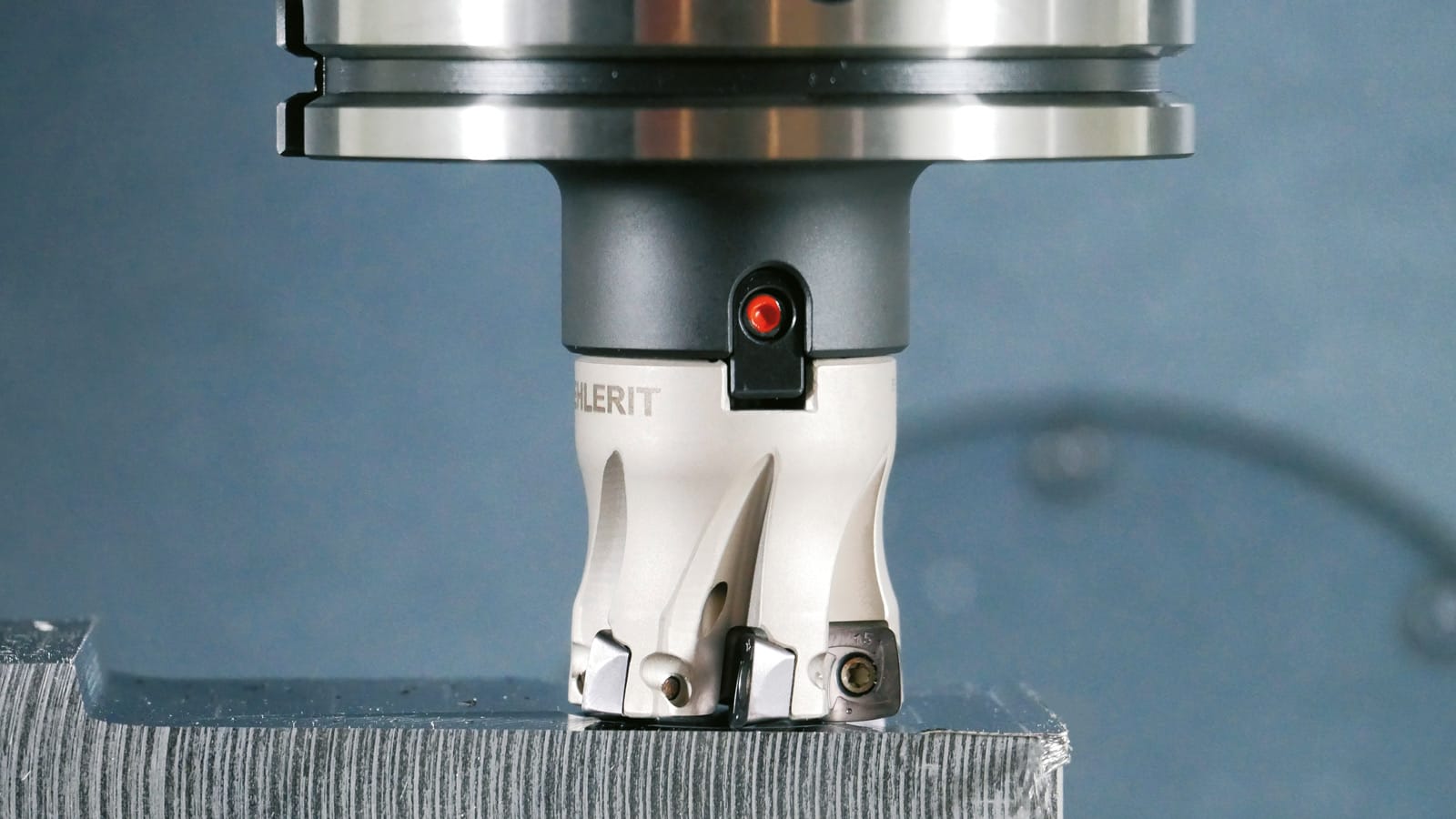

HiPIMS opens up new markets

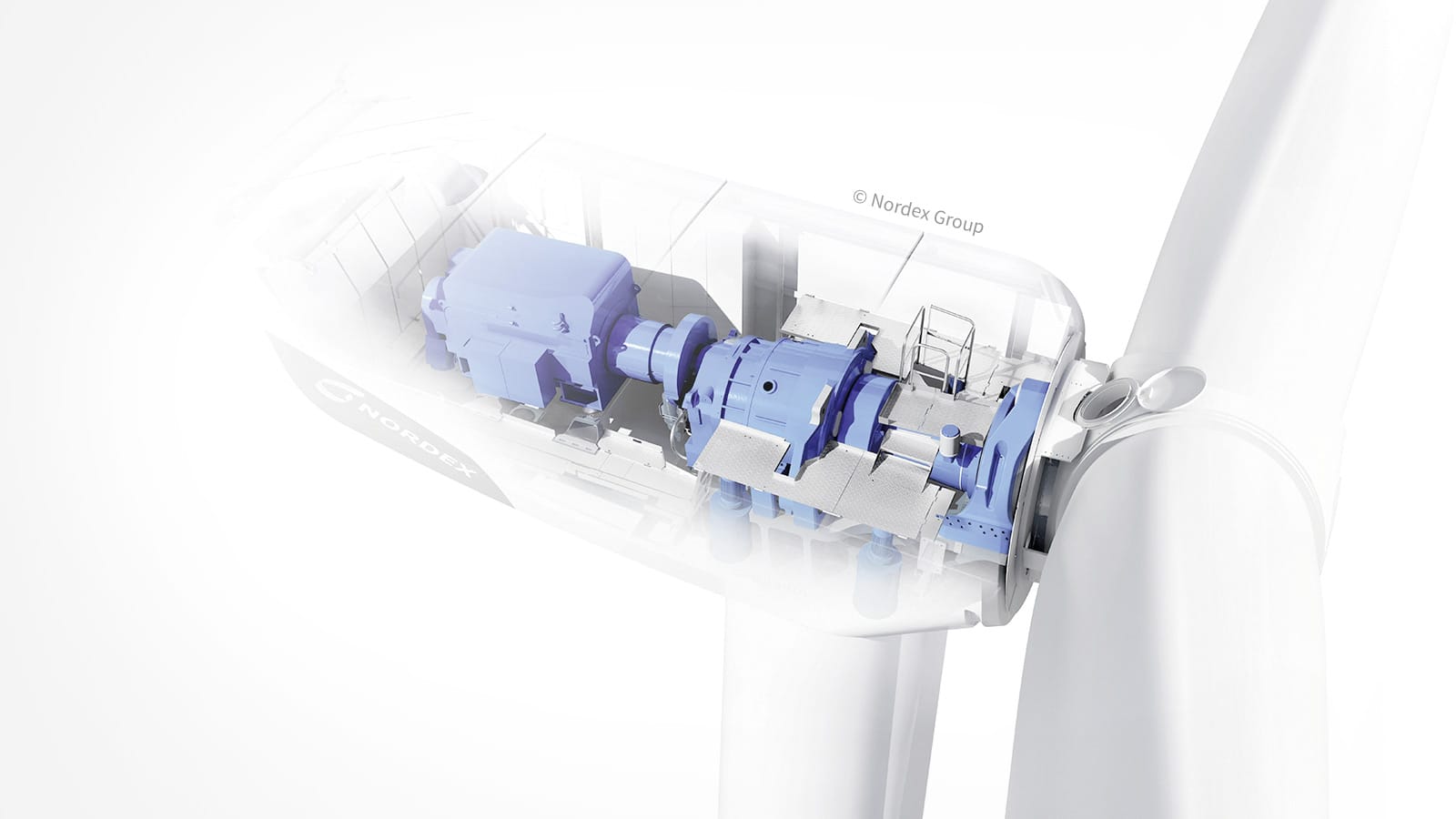

The world of machining is changing. With the transition from the internal combustion engine to alternative drive systems, traditional automotive manufacturing as the most important mainstay for many machining companies and tool manufacturers is being reduced enormously.

Read FACTS STORY